Stationary Tank Monitoring Systems

what you save

Time

All the time your employees used to spend climbing the tanks and measuring the liquid levels manually.

Money

All the money you used to lose on inefficient fuel logistics, worker overtime payments, and emergency trips.

Fuel

All the fuel that could have been stolen or leaked from tank trailers, filling stations, stationary tanks, and fuel dispensers.

Water

All the water overspent or leaked as you didn't have remote access to the water tank.

Take your stationary tanks under control

tank monitoring solutions

How it Works: 4 steps to efficient tank monitoring

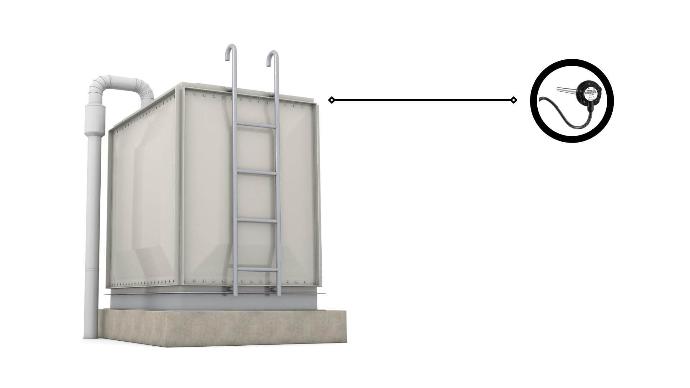

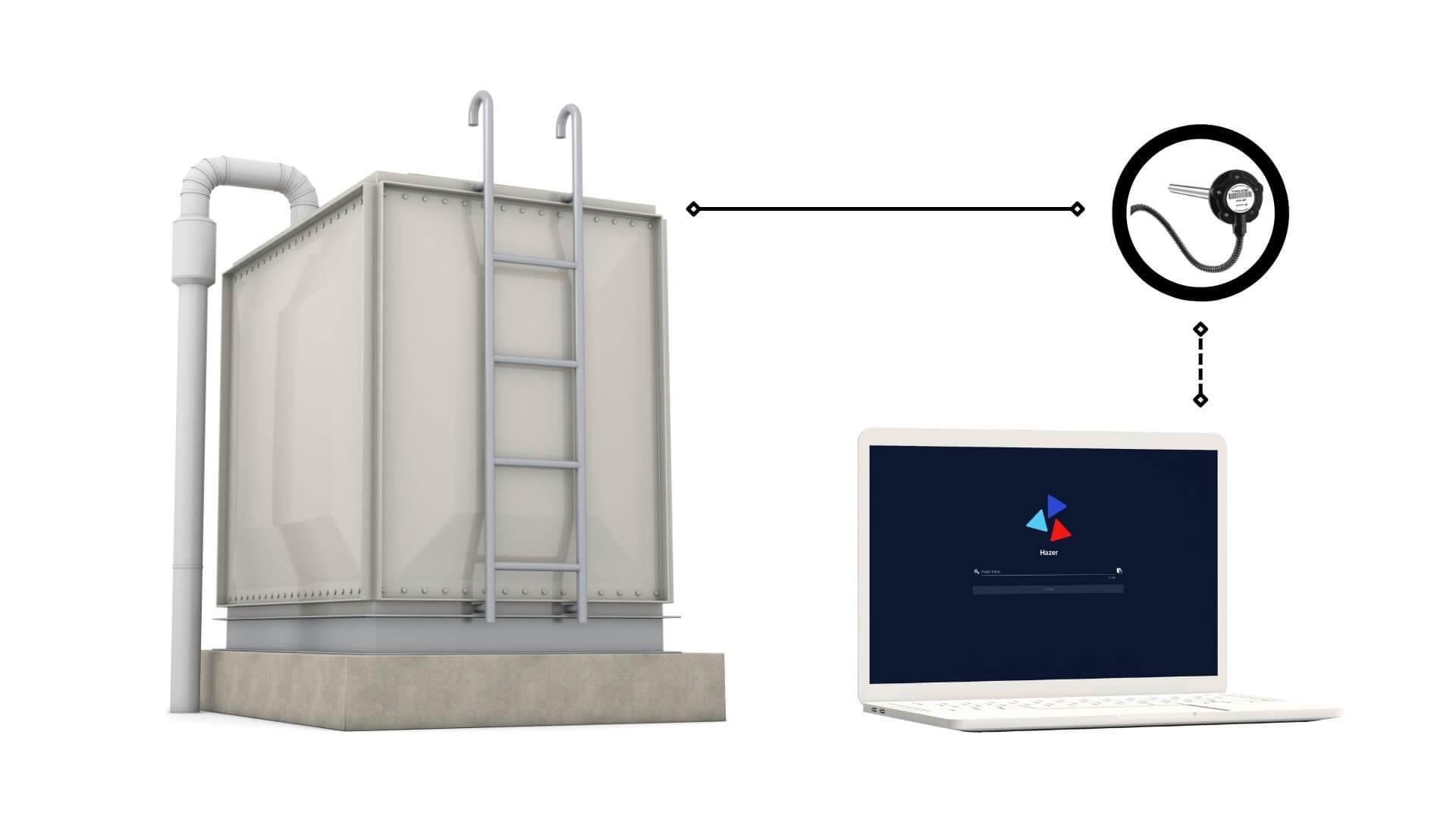

1. Install liquid level sensor

We provide sensors to monitor any liquid material in any tank. The devices can be configured, diagnosed, and updated remotely.

2. Connect it to the IoT

The sensors are pre-configured to work with the cloud IoT software. The devices start sending data immediately after the installation.

3. Configure the software

We set up IoT Dashboards, alerts, & fluid usage reports. Then, we integrate the IoT platform with your in-house software.

4. Enjoy the solution

Having accurate and repeatable data can prevent downtimes associated with running out of fuel or liquid overfilling.